The length of time RCS silica dust stays airborne for can be directly related to the risk of inhalation and consequent illness.

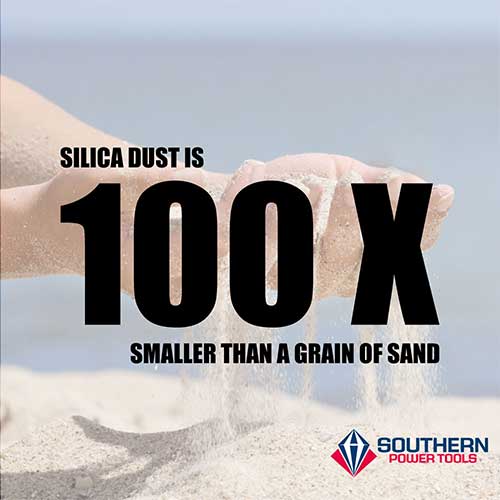

As mentioned in our Respirable Crystalline Silica Dust article, Silica dust is 100x smaller than a grain of sand, this means it will float (invisibly) in the air for a much greater period than the dust you see when the initial work is carried out.

Factors Affecting How Long RCS Silica Dust Stays Airborne

There are many factors which affect how long RCS silica dust can stay airborne, these are mostly determined by location, for example indoors / outdoors, large room / small room etc.

An issue is, in many instances, the location of the task is the one thing you can’t control. Of course, if you can choose to work outside the dust will disperse quicker, whether that means it’s more controlled or not is a different matter and what is for certain, it’s not enough to work outside and assume you are now working safely, you can still be exposed even when working outside.

Just because you cannot see it does not mean it is not there.

How Long Silica Dust Stays Airborne Indoors (The 12-Hour Problem)

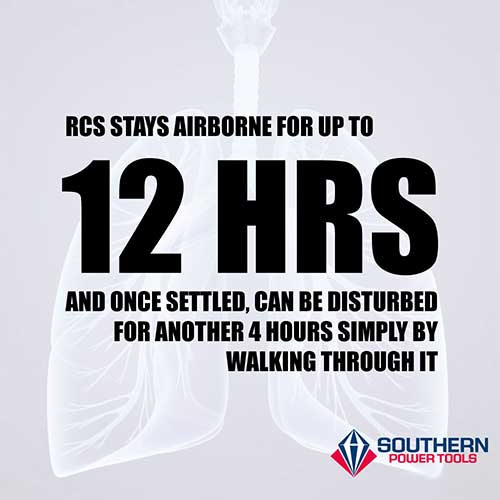

Without suppression or extraction methods in place it is estimated that drilling at eye level height indoors would create RCS that could stay airborne for up to 12 hours. In many cases, it would be completely impractical to prevent access to a room for 12 hours but even if you could, there is still a problem. Silica dust is so light that simply walking into the room after it has settled would disturb it enough to become airborne again, estimates being another for another 4 hours. By waiting you have basically postponed the problem, not dealt with it.

The Risk of Silica Dust Re-release: Thinking Beyond the Task

It’s not just specific activities like drilling or cutting materials that contain crystalline silica that can leave people exposed to silica dust. As well as disturbing fine silica dust when someone cleans up after a task has been finished, the dust can also be released from clothes or surfaces, it can become airborne again when disturbed by people or released when equipment leaks or there’s a spillage.

This is why HSE requires you to have a plan to control exposure, not just for the person creating the dust but also for anyone else who may come in contact with that dust after the work is complete.

In reality the most effective method to ensure the risk from silica dust is fully minimised is to extract at source, we supply a range of equipment that allows you to do this is and can give you an extensive overview of when, why and how you should be using this equipment.

Complying with COSHH Regulations for RCS

If you are working with materials that create RCS (Silica Dust) then you will have to comply with the Control of Substances Hazardous to Health Regulations 2002 (COSHH). To comply with this regulation there are three key things you need to do:

COSHH

Assess The Risks

Control the Risks

Leave A Comment